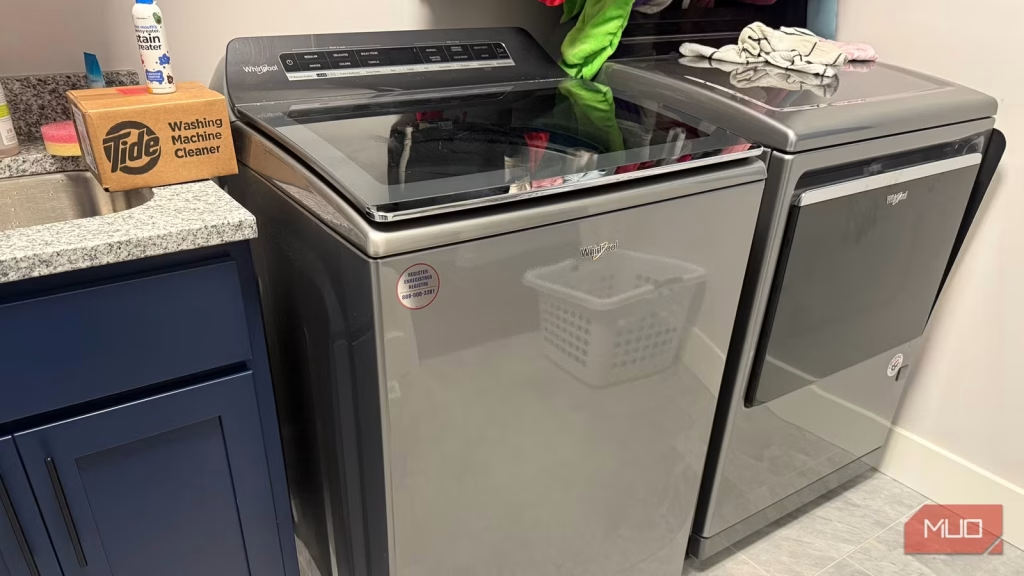

Look, washing machines make noise—that’s just how they work. But there’s a difference between the normal hum of a machine doing its job and the little sounds that mean something’s going wrong. I’ve been through several washing machines in my life, and my current Whirlpool top-loader has been running for over three years now. Here’s what I’ve figured out: those quiet sounds you barely notice are the ones that matter most.

A faint click here, a gentle hum there, and suddenly you’re looking at a $200 repair bill or worse. I avoid harsh cleaners and monitor mine through the Whirlpool app, which helps me catch issues early. However, nothing beats knowing what sounds are normal and which ones mean trouble. I spent time digging through forums and talking with repair techs to figure out which sounds actually matter. Catch these problems early, and you won’t be dealing with a dead machine or a flooded laundry room.

A faint clicking during the wash cycle

What it means and how to fix it

Hear that rhythmic clicking during the wash? It’s probably your agitator dogs wearing out. These are the small plastic cogs inside the agitator that help it grip and turn. If you wash a lot of jeans or towels, they wear down faster.

It could also be your lid lock. A few clicks per cycle is normal, but constant clicking means something’s blocking it from latching properly. I’ve caught this through my Whirlpool app when it sends notifications about cycle interruptions.

Sometimes it’s simpler—coins, buttons, or bra wires trapped in the drum or filter create that distinct sound. A quarter worked its way into my filter once and created a racket for two weeks.

Turn the drum by hand when the machine is off. If you hear clicking, something’s loose or broken inside. Check your pockets before every load and inspect the filter monthly. Agitator dogs cost $10–$20, and you can replace them yourself with a screwdriver.

If the clicking gets louder or becomes constant, don’t wait. What starts minor can turn into a broken agitator or damaged drum.

Subtle humming when the machine isn’t running

Why this is a red flag

I woke up at 2 AM once to a faint humming from my laundry room. The machine was off—or should have been. That humming meant the drain pump was activating when it had no business running.

A washing machine that hums when idle usually has a control board issue. The board is sending signals to the pump when there’s no water and no cycle running. Your electric meter is spinning, and that pump is getting worked for no reason. Eventually, it’ll burn out.

Whirlpool has a known issue with certain models doing exactly this. They’ve repaired some units for free under service bulletins. When you hear this, unplug it right away. Look up your model number to see if there’s a service bulletin available.

Here’s the test: unplug it, count to 30, and plug it back in. If the humming starts up again in under 10 seconds, your controller’s shot, and you need someone to fix it. I’ve read about people who let this go for months and ended up replacing the whole pump.

A gentle grinding or rumbling noise

The sound of bearings wearing out

Free, Unsplash https://unsplash.com/photos/5cpBWEl6y6c

Spin your empty drum by hand. It should glide smoothly and quietly. Even a faint rumbling or grinding sound means your tub bearings are starting to wear out.

Bearings let the drum rotate freely. In top-loaders, they sit below the outer tank, supporting the weight of everything. When they fail, the drum wobbles and damages other components. I caught a previous washer making this sound early and had it fixed before it became a bigger issue. The repair tech told me I saved myself $400 or more.

This problem doesn’t get better. That quiet rumble gets louder over the next few months until it sounds like rocks in a dryer. Once it gets bad enough, the drum starts rubbing against the outer tub. It’ll wear through the plastic or even punch a hole in it.

Test this monthly by spinning the drum by hand when the machine is empty and off. Any resistance or noise is a red flag. Bearing replacement typically costs $300-$500. On an older machine, that’s often not worth it.

Don’t overload the drum, and keep your machine level using a spirit level. An off-balance machine wears bearings faster. You can keep your washer healthier and laundry smelling fresh with some simple steps.

Intermittent ticking from the control panel area

Your solenoid valve needs attention

The solenoid valve acts as an electric tap, controlling when water flows in. When it starts ticking during the fill cycle, it’s struggling. The valve might be partially blocked, your water pressure is too low, or the valve itself might be failing.

I track my wash cycles through the Whirlpool app, and one day I noticed my normal 12-minute wash was taking 18 minutes. That’s when I started hearing the ticking from the back, where the water lines connect.

The first thing to check is to verify that both your hot and cold supply valves are fully open. They’re the knobs on the wall behind your washer, and they get bumped all the time when you’re cleaning back there. The inlet screens on your water hoses collect sediment over time. Unscrew the hoses from the back and look for small mesh screens inside the connection ports. Clean these with an old toothbrush, and you might solve it for free.

If cleaning didn’t fix it, the valve’s probably failing. You’re looking at $100–$150 for a service call, or $30–$50 if you buy the part and do it yourself. Don’t let this go—a stuck valve will either flood your machine or keep it from filling.

High-pitched squealing (even if brief)

Belt problems starting

Brief squeals during the spin cycle mean your belt is slipping or wearing out. Not all washers have belts—many newer Whirlpools like mine use direct-drive motors—but if you’ve got an older model, this matters.

I ignored this sound on a previous machine for two weeks. The belt snapped mid-cycle, leaving me with a tub full of soaking wet clothes and a $70 service call. I should have just replaced the belt for $30 when I first heard the noise.

The squeal usually starts right when the spin cycle kicks in, then goes away once the belt warms up and grips better. Don’t let that fool you into thinking it’s fine. That slip is wearing the belt down faster every time it happens.

If there’s a burning rubber smell with the squeal, stop using it. Pull off the back or bottom panel and look at the belt. You’re checking for fraying edges, cracks, or spots where it looks shiny and glazed.

Belt replacement runs $30–$70 in parts and takes about an hour if you know your way around tools. If you’re not comfortable taking apart your washer, call someone; it’s a quick job.

Listen closely and act fast

Your washing machine talks to you through these sounds. It’s telling you something’s wrong before it completely fails. The Whirlpool app helps me stay on top of my cycles, but I still listen after every load. Fixing a $20 problem now beats paying $500 later, or dropping $800 on a new machine.

Spend 30 seconds listening after each load. Those little sounds seem harmless when the machine still works, but they get worse. By the time your washer actually dies, you’re looking at way more damage and a much bigger bill. Pay attention now, and your machine will run for years. Ignore it, and you’ll be scrambling for a repair tech on a Sunday night when you’ve got nothing clean to wear on Monday. And avoid using the wrong cleaners in your washing machine, as this can shorten its lifespan.